Current issue

November/December 2025

Cold plasma moves toward the processing line

Cold plasma could soon move from the lab to the packing line. A 2025 research paper published in Food Production, Processing and Nutrition highlights how cold plasma performs on fresh‑cut fruit, areas it falls short and what processors can realistically expect from the technology for maintaining quality and safety.

Cutting-edge solutions take center stage at EATS 2025

The latest in processing, automation, packaging and food safety technology was on display at EATS 2025, where more than 350 suppliers showcased produce-ready solutions Oct. 28-30 at Chicago’s McCormick Place.

Latest innovations must balance safety, sustainability and efficiency

The fresh produce industry is at a turning point: packaging is no longer just a vessel but a critical tool for ensuring food safety, extending shelf life, improving operational efficiency and meeting evolving consumer expectations.

New tech helping company meet fresh market demands

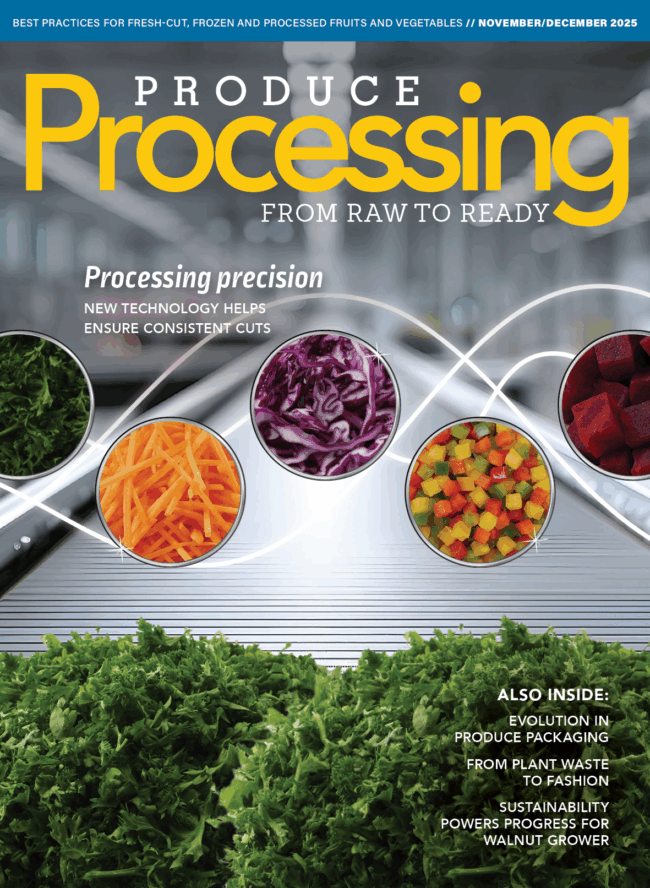

With pressure mounting on cost, consistency and speed, fresh-cut vegetable processors are rethinking their equipment strategy. Companies slicing, dicing or shredding fruits and vegetables at scale face a clear challenge: maintaining consistency and product appeal while keeping operations fast and lean.

Walnut grower future-proofing operations with focus on sustainability

For more than a hundred years, the Barton family has been a cornerstone of California’s walnut industry. Based in Escalon, GoldRiver Orchards has built a reputation for quality, reliability and respect for the land.