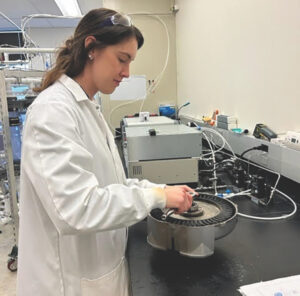

New NanoGuard technology tackles food safety, shelf life

Start-up company NanoGuard Technologies is in the early phases of designing a technology that uses air and electricity to kill molds and pathogens on fruits, vegetables and other food, with a goal of replacing chemical sanitizers throughout the food chain.

NanoGuard Technologies uses High Voltage Atmospheric Cold Plasma (HVACP) to reduce postharvest microbial activity by more than 99%, and cut toxins in half. The process basically pasteurizes raw food without heat in a process NanoGuard calls airilization, which doesn’t affect quality, taste or texture.

The company’s guiding principle is “If it isn’t safe, it isn’t food,” an adage borrowed from the United Nations’ Food and Agriculture Organization, said Larry Clarke, NanoGuard’s CEO.

“Basically, we are moving gasses, air, through a plasma field, creating ionized particles,” Clarke said. “These ionized particles are then blown across the product that needs to be decontaminated.”

The process kills mold, fungi, viruses and mycotoxins, which are toxic compounds produced by some fungi that threaten human, pet and livestock food. NanoGuard has tested the process on fruits and vegetables, including fresh potatoes in storage to reduce rot and cut potatoes to be sold fresh, but the company is currently focusing on the grain and flour industry.

Cargill conducted more than 300,000 tests on animal feed in 2022, according to its World Mycotoxin Report. Of those, 72% were contaminated by mycotoxins, half of which were above Cargill’s “performance risk threshold,” meaning they reduced the effectiveness of the animal feed.

Clarke, a retired Bunge executive, joined NanoGuard after Bunge became a major investor in the company.

Startup investors value joint development agreements between the startups and business partners, and Clarke said NanoGuard has had more than 20 such relationships.

“Finding people who want this to work is easy,” he said. “The work we’re doing right now is not as focused on the fruit and vegetable world, but we have done work there and we see the capabilities.”

That includes treating tomato seeds and an interest in indoor vertical farms.

HVACP in the supply chain

Clarke described airilzation as an “and” technology, not an “or” technology, meaning it’s not limited in use to a specific part of the supply chain, such as during packing, or at the distribution center or even at the retail level. He said he believes the supply chain is “fractured,” with stakeholders focused on just their part of the chain.

“As a warehouseman, I am going to protect my warehouse profitability and effectiveness and efficiency, and as a shipper, I would protect mine,” he said. “But as you move all across the supply chain, there are just a very few companies — Driscolls would be one of them — that sees the whole supply chain and measures the impact of things like food safety across the supply chain.”

The ionized gas used in the NanoGuard process has a short half-life, Clarke said, so the equipment needed to produce it must be on-site. The company has been focused on optimizing the process to ensure it removes pathogens and molds, and is now turning to the practical application of how the equipment would be installed throughout the supply chain.

Tests have involved batch testing, at intervals of 15 minutes to two hours, which is far too long, Clarke said. The goal is to be able to treat products as they move on the conveyor line at packing sheds or processing lines.

“We are in the lab today, optimizing the science of it,” Clarke said. “Now, we’re moving towards the practical application of how we’re going to put this into a company or a processing plant.”

In certifying the service as “safe and effective,” the Food and Drug Administration specifically referred to the company’s process, and not the broad use of ionized gas to treat food.

Clarke said another potential for HVACP is large-scale spatial decontamination, pumping the ionized air throughout a processing room or even a warehouse.

“This is an overstatement, admittedly, but you’d have a clean-room type environment,” he said. “If you clean the product, but put it through (a dirty facility), you’re just recontaminating it.”

Shelf-life extension

A side effect of the HVACP process is extending the shelf life of fresh foods, Clarke said, because it kills the mold, fungi and pathogens that speed up the breakdown of plant tissue.

By prolonging the time food can be consumed, NanoGuard promotes its technology as a way to boost sustainability throughout the supply chain. Food waste is a multi-billion- dollar drain on the food and animal feed industries each year, beginning at the grower level.

“Now you have, and this may be an overused word these days, a real sustainable situation,” Clarke said. “If we’re wasting less food, we’re wasting less fuel, fertilizer, less land.”

The company, founded in 2014, received $6 million in series A funding in 2019. Clarke said the company is preparing for another funding round in the next 12 months.

“Our job right now is to minimize the risk of investing in this technology,” he said.