Maximizing frozen food quality through latest processing technology

Over the past year, consumer demand for frozen foods has grown significantly, and momentum is expected to continue. This growth has led processors to look to equipment manufacturers for assistance in diversifying product lines and improving quality and efficiency.

Four equipment manufacturers — Linde, OctoFrost, Reyco and Tomra — talk trends and what they’re doing to meet processors’ demands.

IQF preserves quality of high value produce

The frozen category that has seen some of the most growth over the last year is the smoothie market, said Chris Johnson, Director of Business Development and Marketing, Linde North America. Growth has been steady in both the retail and home markets. High value produce, such as blueberries, strawberries, pineapple and mango, are popular options for this market.

While much of the growth is due to COVID-19-driven change, Johnson said the category is also booming because of its convenience. Like other companies, Linde has seen considerable growth as a result of this boom, especially where end users are looking to improve quality.

To maintain quality, product needs to be frozen very quickly, Johnson explained in a recent interview. Quick freezing is especially important in products such as strawberries where there is a risk of clumping. Consumers are drawn to IQF products as they can use what they need and return the rest to the freezer without creating unnecessary waste.

When IQF first hit the marketplace it solved a couple of problems, said Johnson. Produce could be frozen individually rather in clumps, which reduced overall waste. Additionally, when produce is frozen slowly it develops ice crystals. At the microscopic level, these ice crystals are large enough to break cell structure, which causes fruits and vegetables to be mushy once thawed, Johnson explained. IQF can be done with Freon or ammonia, but it works best with liquid nitrogen or liquid CO2, he said.

Johnson said Linde’s CRYOLINE UPF (top photo) ultra performance flighted freezer is an attractive option for processors as it locks in moisture, preserves flavor and ensures proper texture. The freezer is ideal for processing higher value products, such as berries, mango and broccoli, said Johnson. It’s also a good option for pre-cooked products, such as fire-roasted vegetables because it stops the cooking process and freezes product quickly.

Product moves on an incline along the flighted belt, and every five feet or so drops vertically. This ensures the product turns and moves, so it does not freeze together.

“Once you get a frozen crust on the outside, then these pieces will no longer have such a desire to stick together,” said Johnson.

Additionally, using a wider belt width results in shorter tunnel lengths, which allows processors to maximize throughput while conserving valuable floor space.

CRYOLINE UPF is a good option for those looking to maximize yield and production capacity while maintaining quality and lowering freezing costs.

“This is not the least expensive way to freeze, but it definitely is the best,” he said.

Removing excess moisture

Prior to freezing, fruits and vegetables are often covered in surface moisture. Most vegetable products, after they have been washed and blanched carry about 8% moisture by weight with them into the freezer, explained Brian Scott, sales and marketing Manager, Reyco Systems. If the excess moisture is not removed, the individual pieces will freeze together. To do this, Reyco developed the WaterVac.

WaterVac is a suction plenum that’s mounted below the entry belt on a standard IQF freezer. Surface moisture is pulled off fruits and vegetable products prior to freezing, which reduces clumping. An additional benefit of the WaterVac is that it reduces freezer defrost times by up to 50%, which lowers overall production downtime.

Reducing waste, improving quality

As consumer demand for frozen fruits and vegetables rises, many processors will look to boost on-site production capacity. But as they boost production, they’ll also want to retain quality to reduce claims. Tomra Sales Manager Frank de Brauwer said the Nimbus sorter helps processors do just that.

Nimbus is a free-fall sorter that removes product with unwanted discoloration, foreign material, deformed products, mold and insect damage. Nimbus can be equipped with two types of scanners, the standard biometric signature identification (BSI) module that removes foreign material, or the BSI+ module that uses a wider spectrum to detect product irregularities as well as foreign material.

Tomra’s unique BSI detects the biometric signature of objects, including the slightest shades of chlorophyll.

“So we are more precise at detecting, and also more precise at rejecting,” said De Brauwer.

BSI technology improves efficiency in two ways, he said, pointing to improved quality and reduced waste.

Nimbus fits easily in the processing line, and is optimal for positioning with the output of IQF tunnels or packaging lines.

Focus on sanitation and food safety crucial

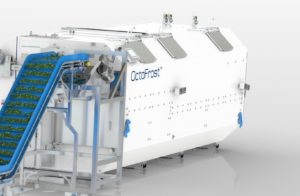

While quality and efficiency improvements and waste reduction are all attractive benefits of investments in new processing equipment, improved sanitation and food safety are also big draws. This is where OctoFrost excels, said Johan Eidfelt, vice president of operations. The company offers blanching, chilling and freezing equipment for all sorts of processed foods, including fruits and vegetables.

As food recalls increase, the USDA and FDA have increased inspections, putting pressure on processors to improve sanitation. OctoFrost addresses these concerns through hygienic design. Their IQF freezer, for instance, used patented bedplates that can be quickly and easily removed during the cleaning process. Typically, this is the hardest part of the freezer to clean, said Eidfelt, and it’s also where most residues are found.

All of OctoFrost’s IQF processing solutions are designed with hygiene in mind. Equipment has rounded corners, no joints, and sloping surfaces for easy drainage and efficient cleaning.

OctoFrost has also seen tremendous growth in recent years. Some is due to growth in the frozen category and COVID-19, but some is due to surging interest in plant-based protein products, plant-based products that replace traditional products, such as cauliflower rice and pizza crusts, and high-antioxidant products, such as berries, that benefit health. Eidfelt expects this market will continue to grow.

Top photo: Linde’s vegetable freezing line