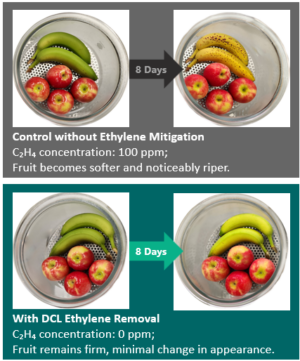

New catalytic system targets ethylene gas buildup to slow ripening

An innovation from catalytic technology company DCL International, part of the DCL Technology Group, aims to slow the ripening of fruit and extend its shelf life during storage and transportation.

DCL’s low-temperature catalytic system is engineered to remove ethylene gas buildup, which helps prevent premature aging during long-distance shipping and controlled atmosphere storage, according to a news release. The catalyst operates efficiently at refrigeration temperatures and under high-humidity conditions, suiting it for produce storage rooms, transport containers and reefer trailers.

Preliminary lab and pilot tests showed reduced ripening over an 8-day period, according to the release.

“At DCL, we’re committed to advancing technologies that reduce waste and create more sustainable supply chains,” Shazam Williams, DCL International technical director, said. “Our new fruit preservation catalyst not only operates under the demanding conditions of refrigerated storage but does so without the use of sprays or chemicals, making it ideal for sensitive or organic produce. This innovation reflects our mission to solve real-world problems with high-impact engineering.”

Nearly 13.2% of all global food waste happens during fruit transport and storage, with unmanaged ethylene gas a major contributor, according to the release.

Additional features of the new DCL catalyst include:

- No chemical sprays: Unlike 1-Methylcyclopropene (1-MCP) treatments, DCL’s system is non-toxic and compatible with organic produce

- Low-temperature performance: Functions effectively at 4°C in humid, cold storage environments

- Self-regenerating catalyst: Built in-house and regenerates using waste heat or ambient air without external energy input

- Maintenance-free operation: No need for manual replacement, cleaning or service

- Flexible integration: Fits refrigeration units on storage rooms, trailers and shipping containers

The system technology is protected under initial U.S and Canadian patent filings, according to the company.

“Food preservation is no longer just a packaging problem. It’s a global engineering challenge,” Williams said. “With billions of dollars lost each year to spoilage, DCL’s fruit preservation catalyst opens new possibilities for producers, shippers and retailers seeking reliable, chemical-free preservation solutions.”

Field trials with commercial storage operators are in the works, and DCL is engaging agricultural, logistics and food storage industry partners to expand field deployment and commercialization, according to the release.