Upstart and established companies strive to define, achieve sustainability

When she formed her company, Earthcycle, nearly 20 years ago, Shannon Boase had a simple, if lofty, goal. “My purpose when I set up the company in 2005 was to save the planet, to do my part,” she said.

These days, Boase is taking bigger steps to reach that goal than she ever imagined. Boase sold Earthcycle in 2013 to Canadian food packaging company CKF Inc. The capital at the disposal of global manufacturer CKF, with eight production sites (two in the U.S.) and 1,100 employees, amplified Boase’s ambition.

Expanded reach

That enhanced reach was exemplified by last month’s launch of a new production line at CKF’s Langely, British Columbia, facility. The line will enhance the production capacity for Earthcycle, now Forest Stewardship Council-certified, home-compostable and widely recyclable, while meeting increasing consumer demand for more environmentally sustainable packaging and creating 20 jobs.

Boase, now senior director of new market development for CKF, said the new line makes CKF the largest global thermoformed molded pulp manufacturer for the fruit and vegetable packaging market.

In April, the company partnered with Belmark Inc. for a retail trail with blueberries aimed at reducing plastic usage. The Earthcycle-branded EC 652 is an 18-ounce top seal blueberry punnet designed to easily slip into automated packing lines with existing top seal tooling. The trial aims to, among other goals, extend shelf life while using a package made of 80% less plastic.

Such projects feed into CKF’s concept of sustainability, which include a reduced carbon footprint fueled by the most economical transport options — another goal the new production line will help the company achieve.

“It is really focusing on the end of life of the product,” Boase said. “What does the consumer do with this product after they’ve used it, and how easy is it for it to be recycled?

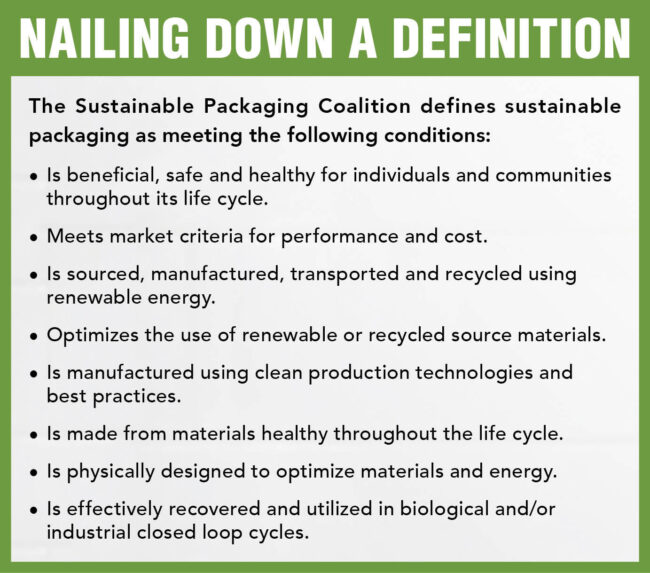

“(Sustainability) is not an easy question. It’s quite nebulous.”

A sustainable history

Fox Packaging has strived for sustainability for much of its 61-year history. A leader in flexible packaging solutions for fresh produce growers and packers across North and South America, Fox’s products include mesh and mesh combo produce bags as well as automated baggers.

“Ultimately, the packaging just goes on the journey with the produce, from the packaging house to the store and then ultimately to the consumers’ home,” said Victoria Lopez, marketing and brand manager for Fox Packaging and Fox Solutions. “The packaging is supposed to support that journey, and I think that’s where sustainability is really enforced. Not where it begins, but where it’s enforced.

“Sustainability really is, in Fox Packaging’s point of view, what is best for the products, what increases the chance of that product being selected and eaten — because food waste is just as impactful on sustainable actions as almost anything else.”

Sustainability factors into everything from research and development to ongoing automation at Fox. Baggers that can produce up to 30 bags per minute increase output and reduce labor and energy use, but advances can come at costs, such as more expensive alternative materials, that have to be absorbed, Lopez said.

Sustainability factors into everything from research and development to ongoing automation at Fox. Baggers that can produce up to 30 bags per minute increase output and reduce labor and energy use, but advances can come at costs, such as more expensive alternative materials, that have to be absorbed, Lopez said.

“We have to be very transparent, and I think that’s the other component of sustainability, is where are we accurately, realistically, and where could we be feasibly?” she shared. “Where can we be in a year? What are the incremental improvements that we can make without impacting the packing houses? … Sustainability is really just making a mindful and responsible choice that fits what your operation’s mission is.”

Pushing the boundaries

Tychon Packaging’s mission is to achieve sustainability through greater reusability.

“We understood that there’s a need to have fully recyclable items that are sustainable and reusable,” Kevin Kantati, president and CEO for Tychon Packaging, said. “I think where the market needs to trend to is reusing things — not just throwing it into the garden and hoping it actually does compost.”

Tychon, a provider of cannabis packaging for more than six years, recently entered the produce packaging market with TychonVert, a supplier offering fully recyclable, compostable and biodegradable options including pre- printed pouches, clamshells, lidding film, bowls for lidding film and trays.

Based in Leamington, Ontario, Tychon began as a produce industry supplier in 2018 before seizing opportunity in Canada’s growing cannabis market.

When possible, TychonVert’s products are 100% PET (polyethylene terephthalate), and the company aims to make as much of its packaging as possible from post-consumer recycled (PCR) content, Kantati said.

“That’s where I’d like to see it go — where everything is recyclable plastic that’s being recycled back into the industry, for less of a footprint of trash,” he said.