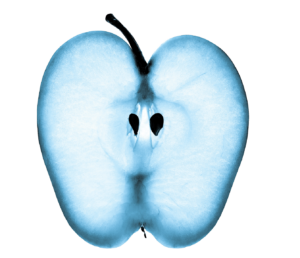

Modern X-ray systems can multitask to ensure food safety

By utilizing density differences and analyzing the resulting greyscale X-ray images, X-ray inspection equipment has moved beyond product safety into other areas of quality control for various product and packaging types.

In addition to detecting foreign bodies, modern X-ray systems are multitasking defenders of product and brand quality. In a single pass at high line speeds, X-ray systems can perform several inspection tasks simultaneously, including:

- Measuring product length, weight, width, area and volume

- Identifying missing or broken products

- Monitoring fill levels

- Measuring mass

- Inspecting for food trapped in seals

Measuring the length, width, area and volume of a product, in conjunction with contaminant detection, is the simplest form of product inspection. The process is known as object finder.

An X-ray image is a grayscale image. The darker the gray, the more product is in the path of the X-ray beam. The software uses grayscale values to calculate, for example, the area of the product.

This type of image analysis takes quality control to a new level. It identifies products that don’t look right, even if they’re the correct weight, in the correct position and free of foreign bodies. It’s hugely useful for manufacturers of products that depend on visual appeal.

X-ray inspection will also detect faulty and missing products. The detection of damaged products relies on the same principles as length and volume measurement. By setting minimum and maximum sizes for pack width, height, volume or surface area, X-ray analysis software can spot a deformed product.

X-ray systems can provide a look inside the final sealed packaging to check that all components are present. It can count components that cannot be seen by cameras or human eyesight.

If X-ray inspection can identify objects that shouldn’t be in a pack, it can also find ones that should be there, such as desiccants for packaged foods.

MASS AND FILL LEVELS

Maintaining the correct mass and fill levels of a product is a constant challenge in food manufacturing. Measuring overfills and under fills affects manufacturing costs as well as consumer satisfaction.

X-ray inspection can analyze:

- The overall mass of a product

- The individual masses within various zones or compartments of a product

- The overall fill level of a product

- The individual fill levels within various zones of compartments of a product

X-ray software uses the combination of the grayscale values and 2D image to calculate how much product or contaminant is in the pack. This volumetric check is also used for mass measurement.

Some X-ray systems have an auto-learn function whereby an acceptable weight pack (close to the nominal weight) is passed through the x-ray system, typically 10 times. The gross weight of the pack is then entered into the system. (The user must have previously weighed this pack on a set of calibrated static scales offering a suitable weight range and accuracy.)

The analytical software can calculate the weight of subsequent packs by comparison to the weight of its learned reference pack. The X-ray inspection system can now compare all future products against its ideal reference product. If the calculated mass deviates from a programmed tolerance, the package will be rejected.

The X-ray inspection software examines each grayscale X-ray image. If the mass meets the preset standard, the meal passes the test. If it fails, it’s rejected from the line and the manufacturer can adjust the equipment.

Using a single product auto-learn feature is quite accurate when production pack weights are near the target weight. More sophisticated systems use a three product auto-learn process: the low rejection point, the target weight and the high rejection point. This method allows calculation of the mass from variations in X-ray absorption within a narrower range and provides greater accuracy.

Accuracy of mass measurement is good on homogeneous packs (e.g. a block of butter), but not as good on loose packed products (e.g. sausages in a bag or products for which ingredients can vary between batches). X-ray mass measurement is particularly effective for high-speed applications where traditional in-line weighing systems may not offer the same level of accuracy.

ZONED MASS MEASUREMENTS

ZONED MASS MEASUREMENTS

For products that are in defined compartments, such as a two-compartment ready meal, mass measurement can provide results for each individual zone/compartment. It lets manufacturers check the overall mass of a product and the masses within each compartment.

By contrast, fill-level inspection is a 2D process based on a simple inspection process: products that fall outside maximum and minimum fill levels are rejected. It doesn’t matter what the product is made of or its mass. It simply has to reach a certain height within the pack or container.

Manufacturers who need an inspection machine to detect contaminants in their food and beverage products must decide what type of system will best get the job done, taking into consideration the type of application, likely contaminants, product packaging, production speed, floor space and budget.

Metal detectors are a good choice when metal is the likely contaminant, while an X-ray machine provides additional functionalities beyond detecting just metal contaminants. X-ray also detects bone, stone, glass and high-density plastic and rubber compounds.

In a single pass at high line speeds, a multi-tasking X-ray system can also provide simultaneous quality checks such as mass measurement, identification of missing or broken products, fill level monitoring and compromised seal detection.

The detection sensitivity of an X-ray inspection system is not affected by a product’s temperature, moisture or salinity. Additionally, product packaging isn’t an obstacle for X-ray technology, as it can detect contaminants through metalized film.

Editor’s note: This is the second of a two-part series examining the benefits of metal detection and X-ray inspection.

Christy Draus is Eagle Product Inspection’s head of marketing.