New tech helping company meet fresh market demands

With pressure mounting on cost, consistency and speed, fresh-cut vegetable processors are rethinking their equipment strategy. Companies slicing, dicing or shredding fruits and vegetables at scale face a clear challenge: maintaining consistency and product appeal while keeping operations fast and lean.

A new trio of machines from FAM STUMABO, a provider of precision cutting solutions for the food industry, is helping meet those demands.

The trio — Dorphy, Centris 315 and Flexis — delivers faster changeovers, increased throughput and better product quality as rising labor costs, short lead times and growing demand for variety put increased pressure on processors to deliver more with less, according to the company. The machines also help simplify size and produce changeovers and deliver a clean, consistent cut across a variety of vegetables and fruits.

“This trio was engineered with real-world production challenges in mind,” Paul Krechel, FAM STUMABO executive vice president, said. “Our customers need flexible, low-footprint machines that do more with no compromise on the quality of the cut. With Dorphy, Centris 315 and Flexis, they get faster changeovers, consistent product quality and less waste. This directly benefits a company’s bottom line.”

CUTTING EDGE OF VERSATILITY

The three machines offer specific advantages:

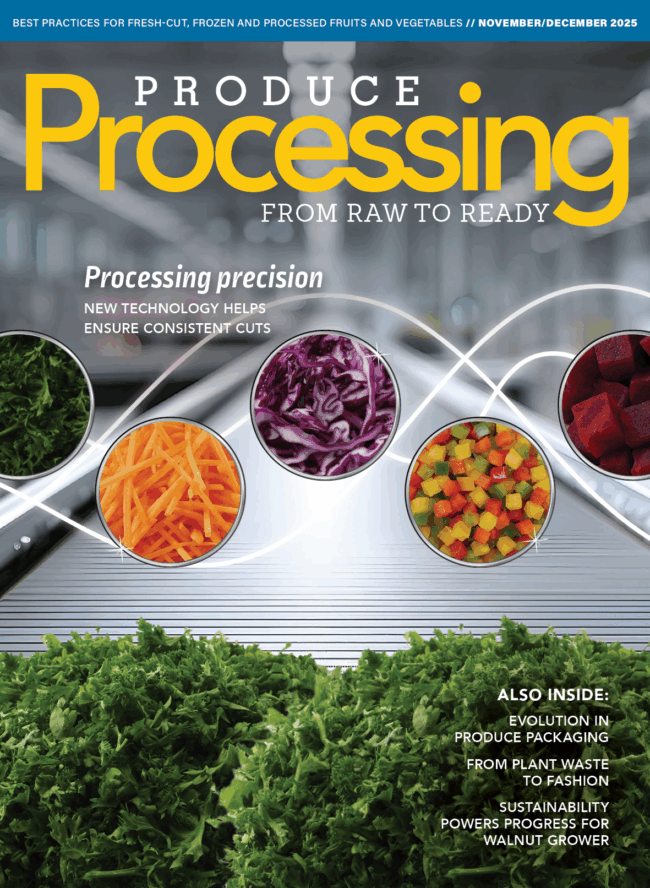

- Dorphy excels at dicing and julienne cutting, making it ideal for firm produce like apples, carrots and peppers used in fruit salads, vegetable mixes or meal kits.

- Centris 315 emphasizes speed and consistency in slicing and shredding both round and elongated vegetables — from cabbage and beets to zucchini — with uniform results.

- Flexis delivers precise cuts of delicate ingredients including leafy greens and herbs, such as romaine, basil and spring onion, without bruising or compromising shelf life.

Whether operating as standalone machines or integrated into a processing line, the trio supports operations ranging from small-batch production to high-throughput environments. Quick tool changeovers and consistent cuts result in longer product shelf life, improved texture and a final product that’s visually appealing and retail-ready.

“To create flavorful meal solutions with vegetables as the key ingredient, it is important that our products have an appetizing look, because customers do not only want a pretty color palette but also perfectly cut strips and dice,” said a spokesperson from HAK Fresh, a fresh produce company in the Netherlands. “Together with FAM STUMABO, we join forces to improve this continuously.”

Speed and adaptability are also essential in today’s market.

“The fresh vegetable segment is under pressure to do everything faster but with more finesse,” Krechel said. “That’s where we come in. With FAM STUMABO’s trio of machines, they can dice, slice, strip cut, and shred faster and more profitably — staying competitive in a segment where every detail matters.”

EXPANDED FOOTPRINT

Based in Belgium, FAM STUMABO has a U.S. office in Sarasota, Florida, and has opened a new U.S. headquarters in Franklin, Wisconsin.

The new facility reflects the company’s move toward direct operations in North America and enables it to serve customers across the U.S., Canada and Mexico with greater speed and flexibility, according to the company.

FAM STUMABO has also opened new facilities in Niederzissen, Germany, and Paterna, Spain, to serve as regional hubs for customer support, technical assistance and in-house testing.

“Our ongoing expansion is part of our long-term strategy to combine global expertise with a strong local presence,” FAM STUMABO CEO Mark Van Hemelrijk said.

“By bringing our teams, test labs and technical support close to our customers, we can better anticipate their needs, respond faster and enable them to stay ahead in a competitive market. We aim to deliver high-performance cutting solutions and, most importantly, to build strong partnerships that help our customers thrive.”

Until recently, FAM STUMABO operated in North America through a distributor primarily focused on the dairy segment. The transition to direct operations enables the company to serve a broader range of industries, including fruits and vegetables, meat and alternative proteins.

The Franklin facility is located near major transportation hubs, improving accessibility for customers across the Midwest and on the West Coast. It features an on-site test lab where customers can send their products for testing or visit the lab for a firsthand experience.

Customers will receive detailed reports, complete with video footage and images, as well as processed sample material. Industrial-grade refrigerated and freezer storage maintains product quality throughout testing and return shipment, the company said.

“The U.S. market is dynamic and diverse, and to serve it effectively, we need to be close, agile and technically strong,” Krechel said. “From Franklin, we’re ready to support our customers in real time with the tools and expertise they need to stay competitive.”