Cutting-edge leafy greens washing

Given the go-ahead for 2022, Fruit Logistica opened its doors and welcomed over 40,000 visitors. Kronen was there to show off its new leafy greens washers.

It’s been over two years since visitors and exhibitors last met in Berlin, Germany, for the trade fair, which kept equipment suppliers from showcasing new developments in person.

Kronen was there to showcase its GEWA AF and GEWA XL leafy greens washing equipment. In a recent interview, Russell Quandt, Kronen sales manager for the U.S., explained what makes the washers so innovative.

Gentle, efficient, economical

Gentle, efficient and economical are the three words Quandt used when describing Kronen’s new leafy greens washing equipment. A high-value product, leafy greens are delicate and prone to damage from mechanical stress, a problem Quandt said Kronen customers wanted addressed.

Introduced at Fruit Logistica this year, GEWA AF has been years in the making. Its design is driven by the need for a better way to pre-wash leafy greens and remove foreign material, while improving efficiency, reducing water usage and saving energy Quandt explained.

“The idea is to do the best job on the front end so there’s less pressure to perform during the main wash,” he said.

GEWA AF uses “active flume” technology that envelopes product into moving water. Rather than dropping onto a surface and being pulled in by water agitation, the greens go into the wash tank submerged. Paddles and conveyors, which can cause mechanical damage to delicate product, are no longer needed, which means delicate greens — kale, iceberg lettuce, baby greens, spinach, and microgreens — are better protected while being thoroughly cleaned. The infeed technology made its first appearance in the GEWA XL, which came to market in 2016.

GEWA AF is an add-on, situated in the wash line before the main washing equipment. Its job is to remove dirt, sand and heavy contaminants. Air bubbles are used to agitate and separate leaf pieces.

“The way Kronen engineers designed air injection to augment the waterflow… it does a phenomenal job,” Quandt said.

The third module within the GEWA AF is a dunking reel, which is used to separate floating trash. The leafy greens are gently submerged, allowing trash and insects to rise to the surface, explained Quandt. The trash is then skimmed out while inside the drum. From there the greens are discharged and conveyed to an optional freshwater rinse.

Another feature that makes the GEWA AF attractive is its water efficiency, as it recirculates water after filtering out impurities. Whereas standard systems tend to use a 10:1 water to product ratio, GEWA AF uses a 4:1 ratio.

“Changing the design of how product is washed from the get go, we’re able to do it with a lower water-to-product ratio and improve the process at the same time,” Quandt said.

GEWA AF also has a clean in place (CIP) system, which helps keep the equipment itself sanitary with minimal operator input. Self-contained nozzles clean the machine at critical parts of the machine, explained Quandt. Designed with hygiene in mind, GEWA AF and XL have rounded corners, are made entirely of stainless steel and have minimal moving parts. This makes them easy to clean and maintain.

GEWA AF requires 370 gallons of water. It washes baby leaf lettuce at a capacity of 880 to 3,300 pounds per hour. The GEWA AF can process iceberg lettuce at a rate of up to 6,600 pounds per hour, and baby spinach at up to 2,200 pounds per hour.

The second washer showcased at Fruit Logistica was the GEWA XL, which hit the market one year ago. It is Kronen’s biggest washer, designed for customers who want to wash large volumes at high capacity. It, too, is equipped with the active flume, a feature designed to protect high-value product from mechanical damage. GEWA AF can be paired with GEWA XL as a pre-wash solution that makes the latter even more efficient at its job.

“It’s an expansion of our standard and really successful GEWA series washers, which are known for their effectiveness and efficiency for water agitation and movement in a helical style,” Quandt said.

GEWA XL is equipped with a helical wash system that utilizes 687 gallons of water. Quandt said using a helical wash system provides 10 times the travel space for product without having to extend the equipment itself. The high-capacity washer processes baby leaf lettuce at a capacity of 3,300 pounds per hour, and iceberg lettuce at a rate of up to 11,000 pounds per hour.

The GEWA XL has a unique insect and floating trash removal design that improves this process without the need for a dunking reel. It is equipped with a fresh water rinse at the end of its cycle, and belt discharge for gentle handling. The belt itself has a quick-release feature that allows sanitation crews to get underneath for easy cleaning.

“We design machines that are easily understood and don’t require a lot of talent to operate them, which increases the speed of training,” Quandt said. “People can pick up on how to operate a machine a lot quicker when the design is simple.

“Kronen’s always working on improving the process, improving the machine, and also maintaining the flexibility needed for a variety of products.”

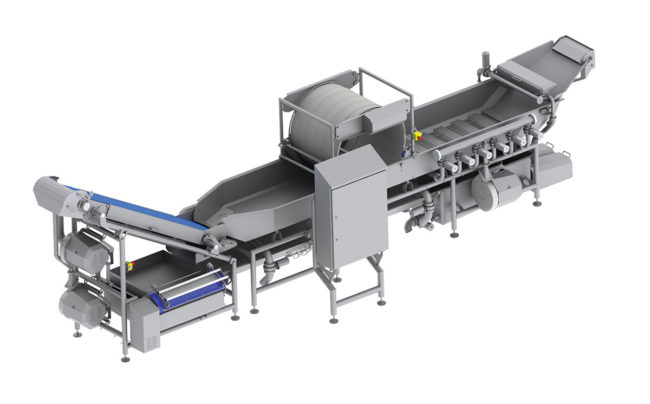

(Top above: Kronen’s washing equipment was designed to accommodate the need for a better way to pre-wash leafy greens. Photos: Kronen)