New tools in assessing fruit quality and maturity

The benefits of being able to assess fruit quality and maturity in the field and in storage are many. Knowing the best time to harvest, store or process fruit can extend shelf life, ensure quality, reduce waste and increase profits. Four companies offer great solutions to help you do just that.

Impact Vision

Impact Vision is a software company that has developed hyper spectral imaging machine-learning software that helps food companies, produce distributors and exporters understand internal quality.

Impact Vision is suitable for assessing everything from dry matter content in avocados to the shelf life of salad to foreign objects in potatoes, said CEO Abi Ramanan.

Impact Vision was one of a cluster of start-up companies featured at Fruit Logistica 2019 in Berlin.

The main advantage of this technology is that it replaces destructive sample-based tests and visual inspection with a fully automated system for quality control.

“You are effectively generating 100 times more information and really improving the way in which products are ripened, sorted and distributed, and this helps to reduce waste,” said Ramanan.

Impact Vision is focused on developing the software, so the company doesn’t manufacture any hardware.

The technology measures chemical composition and the way light reflects based on different molecular structures, so it is able to tell the difference between a mud-covered golf ball and a potato. Hyper spectral imaging is quite new for the food industry. It was developed by NASA, and has slowly made its way to defense and various other industries It’s only in the last couple of years that the price point and the ability to do real-time classification of hyper spectral images has become available, said Ramanan.

What differentiates Impact Vision from its competitors is they’re looking at internal quality. The vast majority of other systems are sorting and grading systems that look at external quality only.

“This is a way to actually optimize supply chains based on the composition of food products themselves,” said Ramanan.

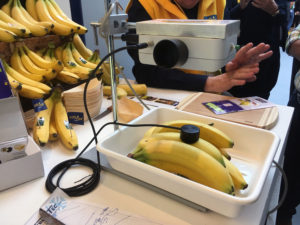

Softripe for bananas

Softripe, the new ripening technology from German company Frigotec, is fully automatic ripening technology that ripens bananas and other tropical fruits homogenously and naturally, according to their biology. In special ripening chambers, the concentration and amount of ethylene gas is regulated just as easily as temperature, oxygen and CO2 levels. The end result is faster ripening, longer shelf life and an optimal acid-sugar balance, which is reflected in taste.

Softripe would not be possible without the color sensor that automatically determines level of ripeness based on color. Using a color camera, a decimal value is shown in the display depending on the amount of ripeness and color gradient. This value reflects the current level of ripeness in a decimal value. The color sensor unit is available in a portable design or as a fixed installation in a ripening chamber.

Softripe was nominated for a Fruit Logistica Innovation Award.

ClariFruit

The ClariFruit app measures fruit quality simply by taking a photo. The user scans the fruit with a built-in phone camera, and with a portable SCiO molecular sensor or spectrometer to capture a wide array of measurements, including BRIX, firmness, dry weight, color, size and bruising, as well as GPS location, weather conditions, and time of sampling.

Measurements are immediately uploaded to the cloud and are instantly processed by an algorithm that compares the measurements to tens of thousands of existing samples from previously inspected fruits.

The algorithm incorporates previously recorded multiple users’ and experts’ feedback, and scientific data with sophisticated machine learning techniques to produce clear and simple grades for scanned fruit’s quality, freshness and ripeness, explained Avi Schwartzer, CEO of ClariFruit.

“ClariFruit can ensure a match between seller and buyers quality requirements and reduce returns or price adjustment quality discussions,” said Schwartzer.

The product is still in the beta testing phase.

RipeTime

RipeTime is an innovative New Zealand-based agri-tech company that has developed an analytical tool to detect and identify the different stages of ripeness in fruit. Using the ES100e Environmental Sensor, which continuously captures ethylene samples from the atmosphere, cool store operators can monitor levels and receive alerts when ethylene rises beyond acceptable levels. This helps ensure produce quality and longevity.

Founder Jon Lowy explains the significance of this technology using kiwis as an example. Zespri, one of the largest marketers of kiwi fruit in the world, asks their post-harvest processors to supply a formal report when ethylene levels rise about 50 ppb. If the fruit has been exposed to too much ethylene, it will not last long, explained Lowy.

“The postharvest processors want to know at 30 ppb so they never reach 50, so they never have to report,” he said.

The picture is very different for apples where acceptable ethylene levels can be as high as 300-400 ppb before there’s a problem, said Lowy.

“Knowing what’s happening is how you manage that process,” said Lowy. “We inform at all of those scales because our sensitivity goes from zero to 10 ppm, so we can cover any of the produce-relevant sectors where they have very divergent concentration targets.”

A U.S patent for RipeTime was granted in 2017.