Kiremko launches Guard technology

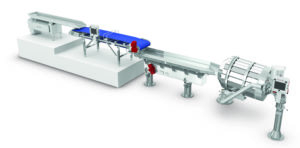

Potato processing equipment company Kiremko launched its new Guard family at Anuga FoodTec in Cologne, Germany in March of this year. The Guard family is a series of advanced data collection systems that support, control and protect potatoes throughout the processing system. Within the processing line each of the Guards has a specific role and provides valuable data to ensure product quality.

Currently the line includes four Guards: PeelGuard, KnifeGuard, DryGuard and WeighGuard. But there are more systems under development. PeelGuard works with Kiremko’s steam peelers, collecting data on all sorts of parameters, including length, black and green spots, remaining peel, processed amount, depth of the removed peel and peel losses. The sensor provides up-to- date information on the quality of the product being peeled. Access to this data allows users to optimize settings and ultimately maximize yield.

“After steam peeling, the system controls what the potato looks like,” said Nicole Peters, marketing and communication manager at Kiremko.

“Then they can adjust the system that goes further into the process line.”

“Then they can adjust the system that goes further into the process line.”

KnifeGuard is a unique knife identification system for the QuadraFlow hydro cutter. The system provides valuable process information by monitoring and maintaining the knife blocks and matching alignment tubes. It does this by using an RFID tag, which is connected with an antenna inside the hydro cutter. KnifeGuard also tracks work hours, providing more insight into how blades are used. Having access to this kind of information can help processors to improve the quality and shape of cut potato products, Peters said.

“They can adjust their system in the process line, so you have better quality,” she said. “We are aiming for the best quality potato in processing – so the best quality fries.”

The third member of the Guard family is DryGuard, an advanced measuring device that collects and combines variables like weight, water content, volume and temperature, and calculates the dry matter content of pre-dried french fries and other potato products. This information is supplied between the drying and frying process and can be used to improve the frying and drying process.

The fourth and final member of the Guard family is WeighGuard, an advanced system for the dosing and weighing of flavoring and additives. The system consists of two separate units: the loss in weight system (WeighGuard LIW) and the weighing belt system (WeighGuard WB). WeighGuard LIW, for instance, ensures accurate dosing of salt, dextrose and other flavorings.

Ultimately, WeighGuard prevents the over- or under-dosing of flavors and additives so the end product is always uniform and of consistent quality. The data gleaned from the Guard systems isn’t used just for making adjustments in the processing line. It can also be used to address issues at the farm level.

“It’s all about the customer and how they run their line,” Peters said. “By constantly checking your process line to see what’s happening in that line through the received data, we can do more.”

At this point in time, the data belongs to the customer and the customer only, Peters said. She did, however, express interest in Kiremko using that data to further improve their technology. “But we are now

focusing on the customer and their line,” she said.

The Guard Family is constantly under development, Peters said. Working in partnership with Tolsma- Grisnich, a company that specializes in potato storage and harvest, Kiremko is developing two new Guard systems. They hope to launch those new systems at Interpom, an international potato event held in November in Kortrijk, Belgium.

“We are talking with Grisnich, for example, to sort potatoes at the store before going into the line,” said Arjan Brouwer, general sales manager, Kiremko. “They also have a scanning machine to scan potato quality – on green, on black, on shape. The goal is to link the information and to use it in the process.”

“I think in five years we’ll be able to link it to the incoming product as well,” he said. “Then you can optimize the process. You can send one batch to one line and another batch to another line. The processor can then make an automated decision – this is going for flakes, or this is going for B-spec, this is going back because it’s off spec.”

Currently, that process is done manually by taking samples at the factory. Five-kilogram samples are taken from each 30-ton truck and manually assessed. It takes 15-20 minutes to assess each batch. By automating the inspection process, they hope to eliminate this step in the process entirely.

“We are constantly searching for the best process for the customer to deal with those situations,” Peters said. “We always say: if you know, you can do something about it.”

“Really, the goal is to go full-flow inspection,” Brouwer said, “the connected factory all along the line.”

-Melanie Epp, contributor