Electric ride: Monarch Tractor driving the future of ag vehicle technology

The first time Praveen Penmesta ever sat in a driver’s seat, he was behind the wheel of a tractor. Now, the CEO and founder of Monarch Tractor is leading a charge to electrify vehicles for agricultural use.

“The first steering wheel that I held was an International Tractor in India on my family’s rice farm. I could not even reach the pedals, so I was just holding onto the steering wheel,” Penmesta said in an interview with Produce Processing. “It’s an emotional connection.

“When we talk to farmers, so much of their livelihood depends on this tractor, and that’s true for farmers around the world. We’re very proud of the fact that in our name itself, we have Monarch Tractor. Yes, it’s not the same as the old diesel tractor, but it’s still a tractor that can change farmers’ economics and also make the food ecosystem more sustainable.”

The growing momentum for electric vehicle (EV) use in ag, from tending row crops to transporting products to market, can also have larger implications throughout the supply chain and in society, said Hillary Leach, ecosystem and portfolio manager, Ag EV, for John Deere.

“There’s an opportunity to be driving infrastructure further into rural communities, and that won’t just help tractors,” Leach said. “There are going to be some second- and third- order effects in the communities where EV is going to come first and be viable. That will be good for the entire process for customers, whether it’s processing or keeping things cold. … We are going to be driving the sustainable solutions where it makes sense for the product and the customer, and ultimately, it’s tied to economic outcomes.”

Rapidly changing tech

Last December, Monarch began delivering its first fully electric smart tractor to commercial growers. The tractor was unveiled two years ago in vineyards, with Constellation Brands, a wine and craft spirits producer, the first purchaser of six Founder Series MK-V tractors.

The autonomous tractors feature 14 hours of battery runtime, 70 peak horsepower, 40 hp continuous, and twice the torque of a comparable conventional tractor. Along with a large charger inside the tractor that can charge the machine in less than six hours, Monarch also offers a battery swap cart to keep the tractor running. Towed behind a pickup truck or tractor, the spare battery can be substituted for the empty battery by one person in less than 10 minutes, Penmesta said. The battery can also utilize solar power.

“We delivered a tractor to a small, zero-emissions dairy farm in New Zealand,” Penmesta said. “They’re using our tractor plugged into solar and a battery system. They’re talking about how they can operate our tractor for like a dollar, because they get to use their own energy.”

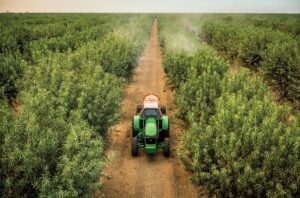

Monarch’s current customer base includes vineyards, orchards and dairy farms, as well as municipal airports and solar farms who find the compact tractor useful for mowing.

“We are very proud of our breadth of adoption,” Penmesta said. “Our tractor essentially can go everywhere a tractor goes, and our current size is the most commonly used tractor size in the tractor world. That gives us opportunities.”

Though Monarch encountered some initial skepticism, users have been impressed with diesel fuel savings as well as increased driver efficiency. Some operations have begun removing the driver from the tractor seat and using that manpower to manage two or more tractors simultaneously.

“There’s been a lot of positive feedback both in terms of power but also range. It is the same thing that we saw in the car world,” Penmesta said.

CNH Industrial, which includes the Case and New Holland brands, is also aboard the EV train. In December 2022, it announced an electric tractor prototype, which will be a Case IH-branded model powered by Monarch EV technology.

Brady Lewis, product manager for emerging products and technology at Case, said more customers, including original equipment manufacturers and those in the construction industry space, are beginning to inquire about EVs.

“Some people have jobs that have specific requirements, in contract emissions or something, where their end customer is saying, ‘I want you to be able to build this building with an electric product or have zero emissions,’” Lewis said. “We’ve also got customers that have their own sustainability goals.”

Case said users have also discovered practical benefits of EVs.

“There’s some customers that are really focused on the benefits of the machine, the performance of the machine,” Lewis said. “The fact that it’s zero noise is a huge factor. They’re not necessarily motivated by the fact that it’s zero emissions. That’s a nice benefit, but they’re looking for a machine that they can operate indoors or that they can operate without impacting the community around them.”

Case is focusing on electrifying small equipment, recently launching two electrified mini excavators. Case has also introduced an electrified compact wheel loader and a small articulated loader model.

“People are surprised at the level of performance versus a diesel machine,” Lewis said. “The machines that we have developed are essentially the same digging performance with attachment capabilities and the power and the feel of the (diesel) machine — sometimes a more impressive power feel than diesel.”

John Deere is also fielding growing customer EV interest, Leach said, mainly from specialty or high-value crop growers such as orchards and vineyards.

“The more a customer runs, the faster EV has a better economic picture, because you’re displacing more diesel, and the energy right now to run a tractor is cheaper,” she said. “Specialty crop customers run a lot. They make a lot of passes in the field. They have this combination of technical viability and the economics playing out very well.”

Already offering electric mowers, John Deere plans to offer electric compact utility tractors by 2026.

The electric future

Sustainability, whether in the form of internal company goals or government regulations or incentives, is only going to become a larger focus, Leach said, so the challenge is to deliver a product to optimize customer operations.

“Farmers have a pretty big task, and that’s feeding the world,” she said. “The sustainability pressures will be there, and so I think by beginning to run at these things now, we have the opportunity to deliver a product that’s going to unlock more value for our customers.”

As advanced as EV technology has become, it still has strides to make. Lewis recalled talking with a potential customer at a recent trade show who was interested in an electric wheel loader for snow blowing — an application that would require 14 hours of operation in cold temperatures in the middle of the night. Existing technology isn’t quite at that point yet, he said.

“Electric machines are not for everyone today, but I think those barriers are getting knocked down every year,” Lewis said. “If we have this conversation two years from now, things will be a lot different. That’s exciting. That’s the fun part.”

Penmesta believes the future of EV is coming into fast focus.

“We definitely see a world where all the small tractors, in the under-150 horsepower class, can all be electric, automated and smart, just like a Monarch tractor, and this will happen sooner than we all expect,” he said. “By 2030, we are seeing a world where most of the new tractors sold will be electric and automated.”

While a fully electric tractor may be different than the one Penmesta grew up with on his family’s rice farm, the technology advances the same goal of helping farmers do their job more efficiently.

“The fact that we’re electric also means that the farmers have more control over their energy. Farmers in rural areas very often struggle with the grid,” he said. “There’s not enough capacity on the grid and not enough resilience. …. With our electric tractor, if you have a number of them along with a swap cart, farmers can take control of the energy site. And not only do they have more savings, they also have more control on when and how they use energy.

“That, combined with the driver-optional features of our tractor, means that they can do more with less.”