A look at steam direct injection processing

Most consumers are willing to give a little leeway when it comes to consistency and fresh produce.

Reasonable folks recognize that the bag of oranges or clamshell of strawberries might not be quite as juicy or sweet as the ones they brought from the same supermarket just a couple of weeks ago.

When it comes to shelf-stable items, whether tomato sauce, salsa or frozen vegetables, there are higher expectations for getting the same product with every purchase. Precise temperature control is key not only in product consistency, but also product safety.

Hydro-Thermal is a leader in steam direct injection heating, a system that is ideal for cooking thick mashes and sauces. Sean Fulton, the company’s vice president of sales, joined Produce Processing for a Q&A.

Produce Processing: Could you give a little snapshot of the history of Hydro-Thermal and how the company has evolved?

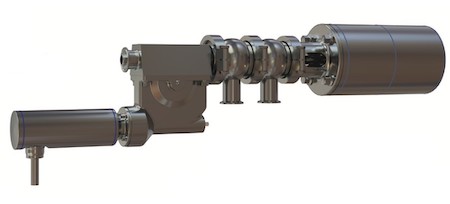

Fulton: Hydro-Thermal is a global leader in on-demand steam injection fluid heating, cooking and processing systems. What began more than 85 years ago with the original Jetcooker Hydroheater in Wisconsin’s paper mills has grown into a worldwide business today with more than 20,000 installs in nearly 90 countries. And in many ways, we’re just getting started. Hydro-Thermal’s latest innovation is the Hydron Sanitary Hydroheater — a 3A sanitary direct steam injection cooker designed for the ultimate process flexibility and stability in an easy-to-use, easy-to-maintain package. It provides shear and pressure control, is fully CIP-able, eliminates burn-on, and is ideal for cooking thick mashes and sauces with ultra-precise temperature control.

How does direct steam injection apply in processing of fruits and vegetables?

Creating a consistent and safe product that looks and tastes the same during every batch can be challenging. Our patented direct steam injection heater (DSI) works by mixing steam and process liquids thoroughly while delivering precise temperature and on-demand heating to ensure product quality.

The versatility of Hydro-Thermal’s heaters is what puts us above other heating systems like heat exchangers. Our DSI heaters can either cook thoroughly inline or cook to a stage of completeness like parboiling, immersion cooking or tank heating — all depending on the process or product’s recipe.

Even at the end of production, DSI heaters are there for packaging. With concerns over recalls, E-coli and other bacterial contamination — heating to exact temperatures for sanitization and pasteurization is critical in the canning process and increasing the product’s shelf life.

DSI heaters can be used for utility or 3A sanitary ingredient water with our Hydron heater. By heating to exact temperatures, processors have greater recipe control ensuring a consistent product. As a result, many customers see a return on investment (ROI) in less than three months.

What are some fruit- or vegetable-based products it has been used for? (I don’t need name brands or companies, just general products, i.e., tomato paste or jams, etc.)

We can heat various products from baby food to tomato paste. DSI heaters also can heat liquid in high-particulate products, such as salsa, while maintaining particulate integrity. In the end, the heaters work specifically with our end user’s recipe without fouling or degradation of the product. The result is a great tasting product, consistent batches, a bacteria-free environment and, ultimately, cost savings.

What question do you hear most from your customers who utilize produce in their products?

The most asked question we get from potential customers thinking about adding a direct steam injection heater is adding water to their recipe and diluting their end product. Yes, using a steam injection heater will add water to the process as the steam used will condense back into the water. But this water can be removed using a flash tank where the heat is released, and the condensate evaporates, generating flash steam and removing the excess water.

The easiest way is to incorporate the condensate into the recipe, adding it to the existing water already captured on an ingredient statement. The general rule of thumb is 1% water for every 10°F of temperature rise. We can provide a water adjustment formula to the product recipe, which adds the sterile condensate making up for the water content that will be subtracted from the recipe. Steam is, in fact, sterile water and doesn’t alter the taste. Many companies incorporate the steam from the DSI heater in their processing systems without issues, and in most cases, the product results in better quality, texture and taste.

What other equipment or technology does Hydro-Thermal have that might apply to produce processing?

Our EZ Heater and EZ Heater Skids are the industry leader in all things hot water. They are workhorses requiring minimal maintenance and easy insulation as they connect directly into the plant utilities. What’s great about our direct steam injection heaters is that there is no lag time meaning on-demand hot water. Which is ideal for cleaning/ washdown and sanitation. We like to say, ‘The perfect temperature, every time,’ and we live by that. Our steam injection heaters save energy by heating fluids to exact temperature the first time, making for quicker startups, reducing set-point temperatures, and improving product

quality. A win-win in our book.