PMMI releases packaging and processing automation white paper

Advancements in automation, both machine and software, are moving manufacturing toward a smarter factory.

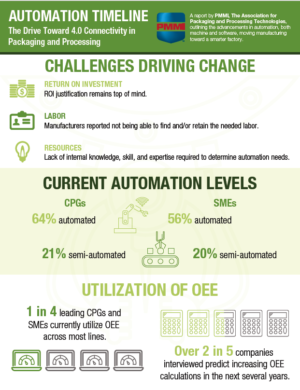

With this expansion comes such challenges as determining return on investment, finding skilled labor and internal resources to assess automation needs, according to the Automation Timeline: The Drive Toward 4.0 Connectivity in Packaging and Processing infographic and white paper from PMMI, The Association for Packaging and Processing Technologies.

Many consumer packaged goods (CPG) companies rely on original equipment manufacturers (OEMs) and technology provider partners for troubleshooting, maintenance training, design and modification, installation and startup, staff training and overall expertise. As this automation timeline advances, PACK EXPO Las Vegas and Healthcare Packaging EXPO 2021 (Sept. 27-29, Las Vegas Convention Center), arrives at a critical time when CPGs and OEMs need to foster strong partnerships in order to overcome automation challenges, implement low maintenance design and improve the reliability of packaging and processing machines.

Many consumer packaged goods (CPG) companies rely on original equipment manufacturers (OEMs) and technology provider partners for troubleshooting, maintenance training, design and modification, installation and startup, staff training and overall expertise. As this automation timeline advances, PACK EXPO Las Vegas and Healthcare Packaging EXPO 2021 (Sept. 27-29, Las Vegas Convention Center), arrives at a critical time when CPGs and OEMs need to foster strong partnerships in order to overcome automation challenges, implement low maintenance design and improve the reliability of packaging and processing machines.

Current automation levels in the packaging and processing industries are at 64% for automated equipment and 21% for semi-automated. The white paper findings show that although COVID-19 has impacted automation plans, manufacturers recognize that that they can improve operations and the broader enterprise by expanding automation strategies and components.

Some of the tools in place driving the future of automation include the Industrial Internet of Things (IIoT) and integration as more machines have data acquisition capabilities and the expansion of robotics in areas such as secondary packaging and palletizing. Additional drivers include incorporating artificial intelligence and predictive analysis used for maintenance.

As manufacturers continue to adopt greater levels of technology and connectivity, a robust cybersecurity strategy is essential. Trends such as remote access and IIoT connectivity make manufacturing more efficient, but they also create new points of vulnerability that bad actors can exploit, as highlighted in PMMI’s 2021 Cybersecurity: Access Your Risk white paper. Given the rise in remote working, these compounding vulnerabilities can leave the manufacturing industry at greater risk of devastating cyberattacks.

Solutions to improve cybersecurity, combat cyberattacks, navigate the automation timeline and safely add connectivity to operations will be on display at PACK EXPO Las Vegas and Healthcare Packaging EXPO 2021, the most comprehensive packaging and processing event in the world this year. It is the one and only place the industry will come together to see today’s changing technology.

Free education on the show floor provides opportunities for attendees not only to see technology in action and talk with suppliers but also to learn about best practices and industry breakthroughs. A few of the on-floor education opportunities include: The Innovation Stage consisting of 30-minute sessions presented by industry experts each day. The Forum includes 45-minute seminars about the latest industry trends with hands-on activities, small group discussion and Q&A sessions. The PACK to the Future Stage will offer 30-minute sessions on advancements such as artificial intelligence, sustainability and more.

As the most comprehensive packaging and processing show in 2021, PACK EXPO Las Vegas and Healthcare Packaging EXPO is the only place the industry is convening, showcasing the most solutions under one roof. To learn more about the advanced packaging solutions that will be on display as well as the educational, networking opportunities and to register, visit packexpolasvegas.com.

PACK EXPO is committed to ensuring your safety while providing the same experience you have come to enjoy at our events. Visit the show website for more information on the PACK Ready health and safety plan.