Key Technology introduces new conveyor for use with metal detector

Key Technology has released a specialized Iso-Flo vibratory conveyor designed specifically for integration with a metal detector to inspect bulk foods on processing and packaging distribution lines. The company said compared to traditional plastic or fabric belt conveyor systems integrated with metal detectors, Key’s vibratory solutions reduce maintenance and minimize product spillage while dramatically improving sanitation to maximize food safety.

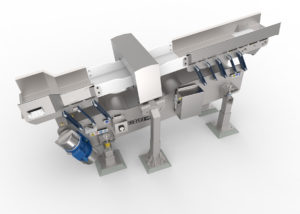

This vibratory conveyor combines three conveyor bed sections – a stainless steel infeed, a non-metallic section that passes through the metal detector’s aperture and a final stainless-steel section with a reject device. The infeed section can incorporate a screen capability to scalp or remove fines, small particles or water, if needed. Reject device options include a pneumatic gate within the shaker bed that opens and closes or a slide chute at the discharge of the shaker bed that switches direction if metal contamination is detected.

The stainless-steel conveyor beds feature a standard rotary polish within the product contact zone or one of several optional finishes to satisfy the needs of each customer. Compared to a typical 2B mill finish, Key said, the rotary polished finish reduces bacterial attachment and biofilm formation. Standard oil-free drives, elastomer isolators, scalloped flat bars, patented stainless steel ground arms and minimal laminations maximize equipment hygiene and help meet rising sanitary standards and regulatory requirements.

“Vibratory shakers offer a lot of sanitation and operational advantages, especially compared to belt conveyors for this application,” said Mark Roedl, area sales manager at Key Technology.

Key said the conveyor is ideal when inspection is needed for frozen fruits and vegetables at the discharge of the freezer and for blanched fruits and vegetables prior to canning, as well as for frozen meat and poultry, shredded cheese and other applications.

Iso-Flo conveyors use independent, frame-mounted drives and spring arm assemblies that distribute energy to all parts of the conveyor bed in a controlled natural-frequency operation. The vibratory motion is contained, creating no noise or interference that could trigger the metal detector to a false reject. The Iso-Flo conveyors are backed by Key’s five-year warranty.