Food processing equipment choice, training key in staying safe

Your employees are much more than a workforce. They are ambassadors of food safety whose knowledge and execution of food safety standards protects both your customers and your brand.

In food processing facilities, though, employee retention is sometimes a challenge. And when turnovers occur too often, food safety training usually takes a hit.

Three food processing equipment manufacturers — Kronen, Jegerings and Sormac — offer tips on how to stay on top of food and workplace safety in an ever-changing environment.

Russell Quandt, Kronen

On choosing equipment

Operators want to be able to access machines quickly and easily, which is why ease-of-use should be top of mind when choosing equipment for high turnover environments.

“Machines that are difficult to use have a negative effect on the people that operate and clean them. They eat up valuable time, which tends to result in shortcuts or lack of interest to do the best job. Operators also like easy access to their machines, so Kronen designs include various doors or removable panels for quick and easy access inside the machines. Better access results in better operation, maintenance and sanitation.”

On training

At Kronen, training is a critical aspect of their customer service package.

“We offer on-site training for operation, maintenance and sanitation, which can be scheduled to accommodate specific needs such as shift change, second and third shifts, sanitation hours, and weekends.”

Going the extra mile

One of the best ways to reduce food safety issues is to choose hygienically designed equipment. While some processors may be concerned about the cost of equipment, Quandt said it pays for itself in the long run.

“Kronen has a tradition of building equipment with a high degree of hygienic design and constant improvement. These design features come with extra costs in the manufacturing process, so our selling prices tend to be higher than machines with lower standards. Buyers need to consider the hygienic design features of equipment when comparing prices. Manufacturers all have the same relative costs of materials and labor, so the only way to offer lower prices is with lower design standards, such as low quality welding (that creates pits/gaps/crevices), stitch welding instead of continuous welds, square corners instead of rounded and angled corners, fixed assemblies instead of quick-attach and detach assemblies, high-quality seal materials, and access doors for easy sanitation and inspection.”

Closing comment

One of the best approaches to minimizing food and workplace safety incidents in high turnover environments is to have an ambassador working the floor at all times.

“I believe this is the best approach. Comprehensive sanitation SOPs are large documents with very specific instructions. A machine operator may not have the ability to remember every specific instruction, especially under the pressures of a typical production shift. Third-party sanitation crews that operate in the off-hours have limited time and limited talent, which increases the risk of SOP failures. Having a person with complete knowledge of the sanitation SOP dedicated to assisting operators and sanitation crews would prevent mistakes and/or short-cuts.”

Featured equipment: Model GS10-2 Belt Slicer

The GS10-2 Belt Slicer offers complete and easy access via hinged doors. All parts in the food contact area can be disassembled without the need for tools.

Quick-release tensioners allow for easy removal of belts. Total disassembly and reassembly can be completed in a few minutes. Upon disassembly, only solid surfaces are left to clean with complete access. All welds are continuous and smooth.

Roy Lemmen, Sormac

On choosing equipment

When choosing equipment for high turnover environments, Roy Lemmen, sales director, Sormac, said ease-of-use is key.

“People do not like to work with machines that we don’t know how to operate or are impossible to fine tune. We develop and build equipment that is easy to operate by using an operator-friendly, easy-to-navigate user interface and minimal settings.”

On training

Sormac prides itself on working closely with its customers and their employees when new equipment is introduced to the work environment.

“During installation we provide training to staff and operators. They explain the in and outs of the equipment. A wide range of our equipment is offered with a Human Machine Interface (HMI) with simplified programs that limit the specific need of knowledge of a single operator to adjust parameters during operation.”

On making improvements

Equipment manufacturers play an important role in improving workplace and food safety standards in work environments with high staff turnover and untrained workers.

“To improve food safety and workplace safety we offer equipment that is efficient, easy to use and environmentally friendly. We think about noise reduction in the direct area and minimizing spilling points, and build according to the latest standards. We believe it is important to listen to our customers.”

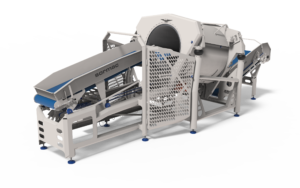

Featured equipment: SC-940 NextGen Centrifuge

Sormac’s SC-940 NextGen centrifuge was designed with food safety as its top priority. The centrifuge is constructed with a plate frame that has no blind spots or hollow frames. The cleaning and maintenance crews benefit from this design, as it make the equipment quick and easy to access and clean.

“We design our machines based on feedback and input from our customers. Less cleaning time lowers overall cleaning costs and creates more time for the maintenance crew in between the busy production shifts.”

Jan Jegerings, Jegerings

On choosing the right equipment

Choosing the right equipment for the task can be tough. Jan Jegerings, owner of Jegerings, a Dutch company that manufactures cutting, drying, peeling and drying machines, said most of his clients are looking at the end result, as in what the equipment can do for the product they sell.

“The quality of output of washed and cut vegetables, for instance, is most important. Ease of use comes second, then reliability, hygienic design and user safety. Of course, user safety and food safety are most important, but when designing, first thing you think of is how to create a machine that will do a perfect job for your customers.”

On hygienic design and ease of use

Getting that perfect cut is the first step to improving overall hygiene, said Jegerings. A perfectly cut product will lose less juice, and juice from fruits and vegetables are food for bacteria.

“When a machine is easy to assemble and disassemble, has smooth surfaces and no dirt angles, then it will be easier to clean thoroughly by the employees. When they do not, the chance that they will ‘forget’ will be much bigger. Our washing machines can be simply and completely (dis-)assembled for cleaning without using any tools.”

On training

At Jegerings, making sure customers know how to use their equipment is part of the service they deliver.

“All customers and employees are welcome to visit our test center for comprehensive training. Because of the foolproof design of our machines most people can get along with just watching our videos our reading the manual. If the customer wants to have training on-site, one of our staff will install the machines and provide the employees with a comprehensive explanation and training.”

Closing comment

Jan Jegerings believes equipment manufacturers play an important role in addressing food and workplace safety through equipment design and redesign.

“Listen to your customers. They often have great ideas for improvements because they work with the machines all day. Be sure to keep up with the newest guidelines regarding hygienic and safety demands. Stay informed of the latest techniques and possibilities.”

Featured equipment: Small-Belt Slicing Machine

Jegerings designed its small-belt slicing machine for use by untrained workers. The operations touchscreen functions in 11 languages using flag icons. The operator then chooses the product and size of cut and the machine does the rest. The easy to assemble and disassemble knife disc, belts and guides make for quick and hygienic cleaning.

“There are sensors on all doors and on the output funnel, so it’s impossible for employees to injure themselves because the machine will immediately stop when opened while rotating. It will also be shown graphically on the touchscreen why the machine has stopped.”

— By Melanie Epp, contributing writer