Automation, flexibility trending in end-of-processing-line packaging

Increasing customer demands coupled with the need for automation and labor reduction make end-of-line packaging a key area for food producers.

We recently checked in with representatives from three companies with expertise in this area. They include Wayne DeCou, Volm’s sales director of equipment and engineered solutions, Peter Fox, president of Somic, and Fox Solutions President Aaron Fox.

What have been some big advancements in end-of-line packaging in recent years?

Wayne DeCou, Volm: Customers are regularly asking for greater flexibility and increased rates. While this regularly increases the complexity of the solutions, the solutions are actually becoming more user-friendly, safer and more repeatable to make changeovers to the equipment. Quality suppliers recognize that not only are the end user’s personnel less available to them, the overall demographic isn’t necessarily getting more experienced so there is greater value being supplied up front in how and where key features are designed and implemented.

Peter Fox, Somic: While the industrial sector has been slow to adapt to new user-friendly human machine interfaces, it has improved quite a bit. There are now more machines that leverage the interface between computer controls and the mechanical output of a machine. The trick is streamlining this interface to make it easier for operators to understand and feel at ease with these control parameters. And the trick for the machine programmer is to make the interface intuitive. Somic has always leaned toward making this interface similar to other devices that an operator would be more familiar with, such as an iPhone.

Aaron Fox, Fox Solutions: Newtec (a Fox Solutions partnering company) weighers — the 4014XB1, for example — are high-speed with extra-large weighhead design with a 14-head weigher for large-sized products and can support packing equipment packaging between 2 pounds to 50 pounds. One weigher can support up to four (of our FSWB3) wicketed baggers or two (FSPB2) pouch baggers, allowing us to partner with brands to build out a line that is specific to their distribution demands and production goals. Then there’s Newtec’s Celox-P-UHD, an optical sorting machine manufactured specifically for potato automation which offers an accurate selection of high-value products by sorting up to 13 categories by consistent quality, size, and shape simultaneously.

For companies looking to expand their capabilities, what do they need to think about?

Fox, Somic: The first thing they need to recognize is that automation is much more expensive than they may be prepared for. They may want to think in terms of modularity. If I automate my case erecting first, continue to hand-pack and then place an auto taper or closer at the end of my line, this may be adequate. The caution here is don’t go cheap. You definitely get what you pay for. My advice is to go with the top tier machines and then simply scale back if you cannot afford the investment — go after the biggest payback first.

DeCou, Volm: Think about where your business and its needs are at today, and try to consider as best you can where those conditions will be in 3-5 years. Ask questions of prospective suppliers what they can offer to meet those needs down the road either by incorporating some value-added benefits now, or in the way of upgrades, and even their approach to trade in against future purchases. Too often the needs of today are being met, but future advancements or capital purchases run out of area to implement them in, which can drive the overall cost of further improvement even higher.

Aaron Fox, Fox: Most often, it is the end-of-line operations that must be considered. Once you’ve invested and expanded your operations, how will you process packed bags at 18 to 25 bpm? Integrated solutions help by streamlining these operations. It’s not necessarily about labor reduction, but about labor reallocation. Rather than designating labor to tedious routine tasks, you can employ automation that packs, stacks, and wraps pallets up to the point of loading the truck.

Any advice on changing in and out different product lines to maximize efficiency?

Aaron Fox, Fox: Downtime and changeover become some of the obstacles when outlining your production schedule. It’s imperative to pack according to size, this minimizes the amount of adjustments that will need to be made to the machine when changing the line over.

DeCou, Volm: Consider changeover as part of your overall cost of doing business and factor the ROI of more repeatable conversions can be to your equipment. Reducing the time of the change is the beginning, but considering the downstream effects of reduced initial quality and intermittent stoppages to regain smooth operation at rate again needs to be factored into your operation. Upfront options to some solutions come at greater initial cost, but pay off over time when implemented effectively.

Peter Fox, Somic: A producer needs to look at this from both ends. Do you really need to provide 12 different customers all with their own formats? Many companies do not recognize the tremendous cost in dealing with different formats, from inventory management to the machine complexity and changeovers, etc. … This is why so many medium-sized companies cannot break into high-volume manufacturing with automated systems. The advice to our customers is to teach your salesforce to sell with discipline and sell what you have or can do efficiently. Perhaps your company can establish a revenue rule — if this unique format is worth $20 million in annual sales, for example, it is a go.

Any other thoughts to share?

Peter Fox, Somic: As the U.S. market inches very slowly toward the optimization of retail-ready package configurations, it would be smart for producers to be prepared for this when it does finally arrive. This means purchasing equipment that has the ultimate flexibility to run a wide variety of these formats, such as cover tray. What is holding the U.S. market back is the perspective that secondary packaging — that is, shipping cases or boxes — are a necessary evil worthy of only cost savings and productivity improvements that are keeping many of the CPGs financially relevant as the innovation drought continues.

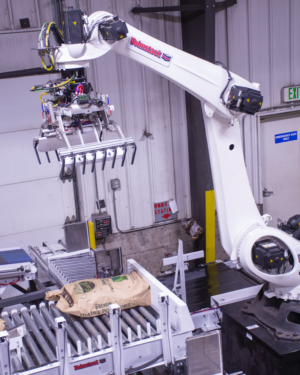

DeCou, Volm: Volm has developed some innovative end-of-line stacking solutions which can automate some of the more difficult to handle manual tasks, such as filling display-ready bins with consumer bags. These solutions have high emphasis on not only speeds, but ease of use and changeover which are recipe driven rather than requiring mechanical modifications. These solutions make use of robotics, conventional palletizing techniques and sometimes a combination of both to attain the best advantage from the strengths of each.

Aaron Fox, Fox: Be future-minded when choosing equipment solutions and partners. Is this equipment expandable? Can it be modified to suit future operational needs? Another consideration is proprietary packaging; our bagger line is responsive to our signature Fox Packaging product line as well as other flexible packaging available on the market.

Top photo: Newtec Spinaflex section products reach the Spinaflex section as they leave the camera section. The Spinaflex belt routes each product to the correct outlet.